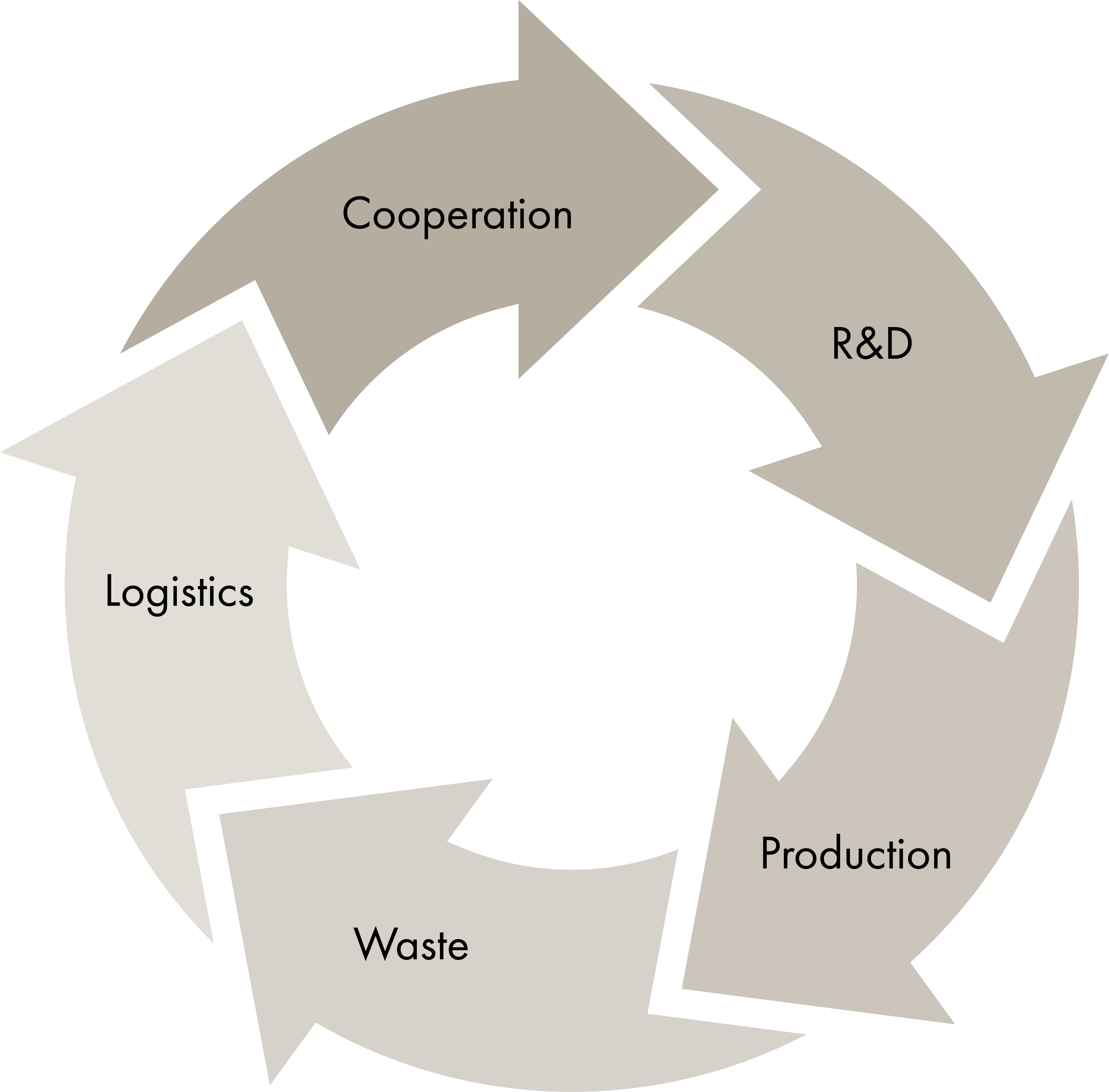

At Modulpac, we see sustainable production as a holistic approach where energy efficiency, resource use, and supply chain management play key roles. We continuously improve to minimize our environmental impact and optimize our processes.

Energy Efficiency – Every Saved Kilowatt Counts

The most sustainable energy is the one never used. Energy efficiency is enabled through:

Energy-efficient injection moulding machines

Optimized production processes and workflows

Continuous investments in new technology

In Process Recycling

To minimize material waste, we use high-performance granulator intended for recycling of sprues. Immediate grinding directly at the injection moulding machine allows the regrind to be returned directly to the process.

Any production scrap we do not reuse internally is sent to our recycling partners, ensuring material is repurposed.

Certified Management System – Quality and Sustainability in Focus

At Modulpac, we have a well-functioning management system that ensures high quality, environmental responsibility, and food safety. We are certified according to:

ISO 9001 – Quality Management

ISO 14001 – Environmental Management

ISO 13485 – Quality Management for Medical Devices

FSSC 22000 – Food Safety Certification

ISCC+ – Traceability in Circular economy

These certifications demonstrate our commitment to continuous improvement, regulatory compliance, and customer satisfaction.

Product Safety – Certified for High Standards

Safety is a top priority at Modulpac, and our products meet strict regulatory requirements.

UN Certification – We provide UN-certified packaging for the safe transport of hazardous goods, ensuring compliance with international safety standards.

Child-Resistant Closures – Many of our closures are designed to meet child-resistant packaging standards, preventing accidental ingestion and ensuring safety in households.

State-of-the-Art Laboratory – Our well-equipped laboratory operates according to ISO 17025, ensuring high precision in testing and validation of our products.

Cleanroom Production – Ensuring high level of product safety and reliability

For industries with the highest hygiene requirements, we offer cleanroom production in an ISO Class 8 environment. Our cleanroom production area is designed to maintain controlled air quality and particle levels. This setup minimizes contamination risks and ensures that our products meet the strict cleanliness and safety standards. We focus on pharmaceutical and medtech applications, delivering solutions that comply with stringent industry regulations.

Modulpac – A part of the community

Modulpac is deeply rooted in Lagan and takes responsibility for its employees. We actively work with health, safety, and well-being, striving to create a workplace where everyone thrives and develops.

For us, well-being is an essential part of a sustainable workplace. That’s why we invest in employee wellness, promoting physical and mental health. Through training and skills development, we provide employees with opportunities to grow and strengthen their expertise, benefiting both individuals and the company.

We believe sustainability is about people, resources, and innovation.