Background and purpose

The EU Packaging and Packaging Waste Regulation (PPWR), formally called Regulation (EU) 2025/40, replaced the directive 94/62EG. It came in to force the 11th of February 2025 and will be applied from the 12th of August 2026. The purpose of the PPWR is to decrease the amount of packaging waste, increase recycling and re-using, limit the usage of harmful substances and promote a circular economy in the EU.

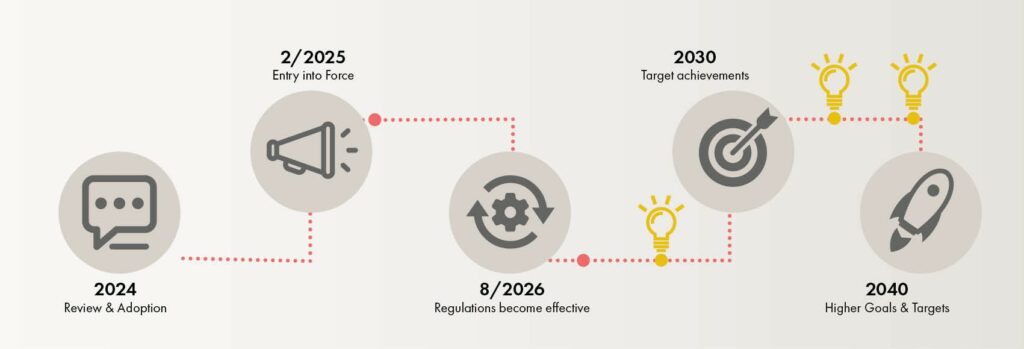

Important dates

- 11th of February 2025: Regulation enters into force.

- 12th of August 2026: Most regulations come into effect, including prohibitions of using PFAS in food packaging.

- 2028: EU commission will adopt guidelines for “Design for Recycling”.

- 2030: All packaging must achieve recycling class A, B, or C. And fulfil the requirements of containing recycled materials.

- 2035: Large-scale recycling requirements and 10% decrease of packaging waste.

- 2038: Only class A and B is allowed for recyclability.

- 2040: Increased requirements for recycled materials and re-use.

Here you can read more about PPWR.

Modulpac act pro-active to the PPWR by a structured and future-oriented working method and has since 2024 had an internal group that constantly following the development of the PPWR. This group analyse the progress of the regulation, interpreters the practical consequences as well as cover the work within ECHA (European Chemicals Agency) around the different substances and how they affect the recycling process. We follow the development of recycled materials, were the EU just discussed the possibility of chemical recycled material from the consumer side which might be allowed in food packaging.

If you want to know more about how Modulpac actively work with these questions, please read more below.

Modulpac´s ways of working connected to the PPWR – Strategic alignment to the EU’s new packaging directives

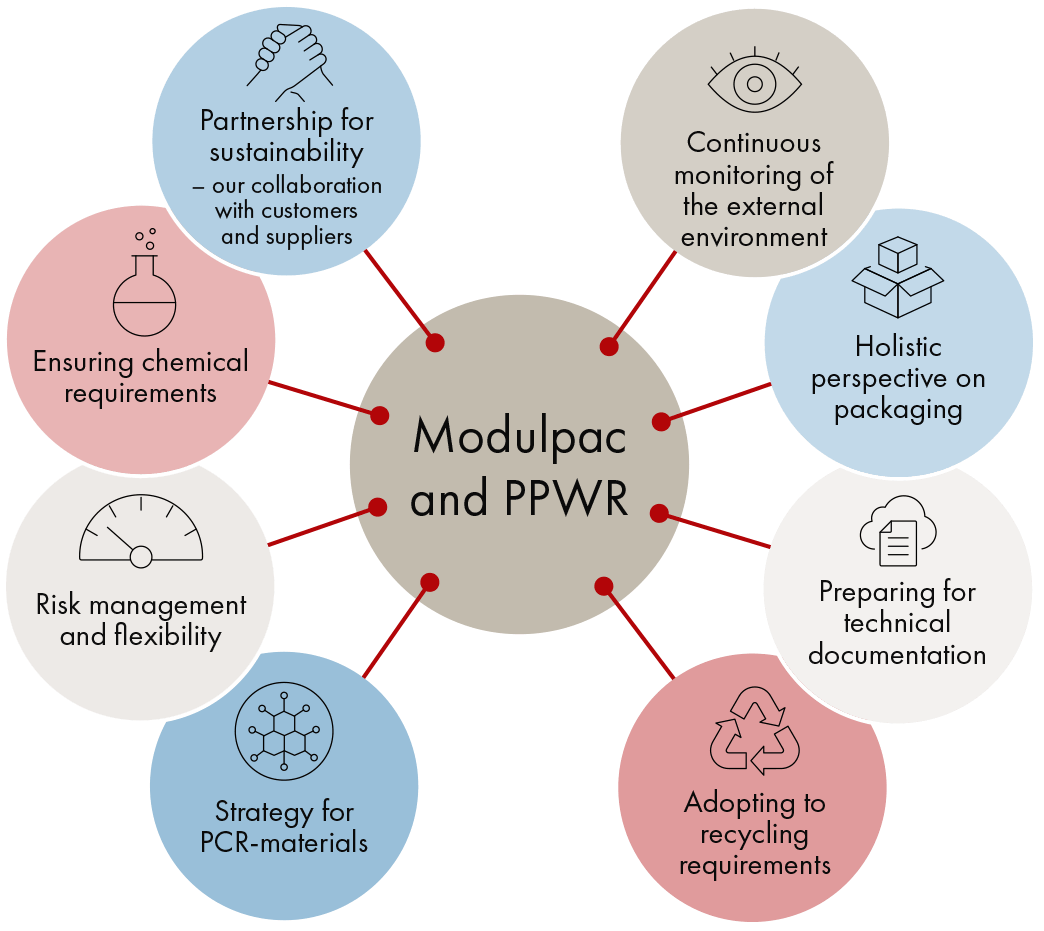

Modulpac act pro-active to the PPWR by a structured and future-oriented working methods. These following points summarize how we work to meet the requirements in the new directives:

Please click on the circles below to read more

Modulpac and PPWR

Continuous monitoring of the external environment

Modulpac is aware of that the PPWR will be updated regularly with new delegated acts and technical guid lines. Because of that we have established routines to follow the development of the legislation and make sure that all relevant parts of the organization keep informed.

Holistic perspective on packaging

The PPWR includes all types of packaging’s – including components like shrink film, labels, plastic trays and pallets hoods. Modulpac will analyse all our products to identify which parts that will be included in these new directives and how it will affect each packaging component.

Preparing for technical documentation

One crucial part of the PPWR is the requirement for suppliers to be able to show that their packaging meets the requirements of the new law. Because of that, Modulpac will develop new updated Declaration of Conformity (DOC) and technical documents for all the products, which will include recycling, choice of materials and design principles.

Adopting to recycling requirements

By 2030, all packaging needs to be recyclable according to Class A, B or C.

Modulpac is working with:

- Make sure that the packaging is designed for material recycling.

- Avoid material combinations that makes sorting difficult.

- Optimize the packaging volume and weight.

From 2038 only Class A and B is allowed, which means that the design requirements are further tightened.

Strategy for PCR-materials

Modulpac analyse how the requirements for recycled materials (PCR) affect different groups of products. Modulpac has worked with recycled materials for many years and has a long experience within this area. We do also see the possibility of using chemical recycled materials and bio-based materials, depending on future decisions from the EU.

Risk management and flexibility

We are aware of that the PPWR contains mechanisms for adjusting requirements. By building flexibility in the production and material strategy, Modulpac can make fast adjustments to changes and directives which include both risks and possibilities. Modulpac has risk management implemented at all levels.

Ensuring chemical requirements

Modulpac is following the development of substances that may be banned in packaging materials, especially PFAS in food packaging. We are working actively to make sure that our packaging fulfils both todays and future chemical requirements.

Partnership for sustainability - Our collaboration with customers and suppliers

To meet the comprehensive requirements in the PPWR, Modulpac is working actively and strategically together with both our customers and suppliers. We see this as a common responsibility were the whole value-chain need to cooperate to reach both a sustainable and regulations adapted packaging.

We have a continuous dialogue with our suppliers to make sure that our choice of materials, design principles and technical specifications fulfils the requirements for recycling, re-using and the contains the minimum requirements for recycled materials (PCR). By sharing information and requirements early in the development process, it helps us to identify areas of improvement and future-proof our products together.

At the same time, we are working closely to our customers to make sure that we understand their needs, inform them about upcoming legal requirements and offer solutions that are both functional and sustainable. We help our customers to understand the legislation, supply them with documents as Declaration of Conformity (DOC), and to give guidance about marking, choice of materials and design for recycling.