Responsibility for a sustainable future

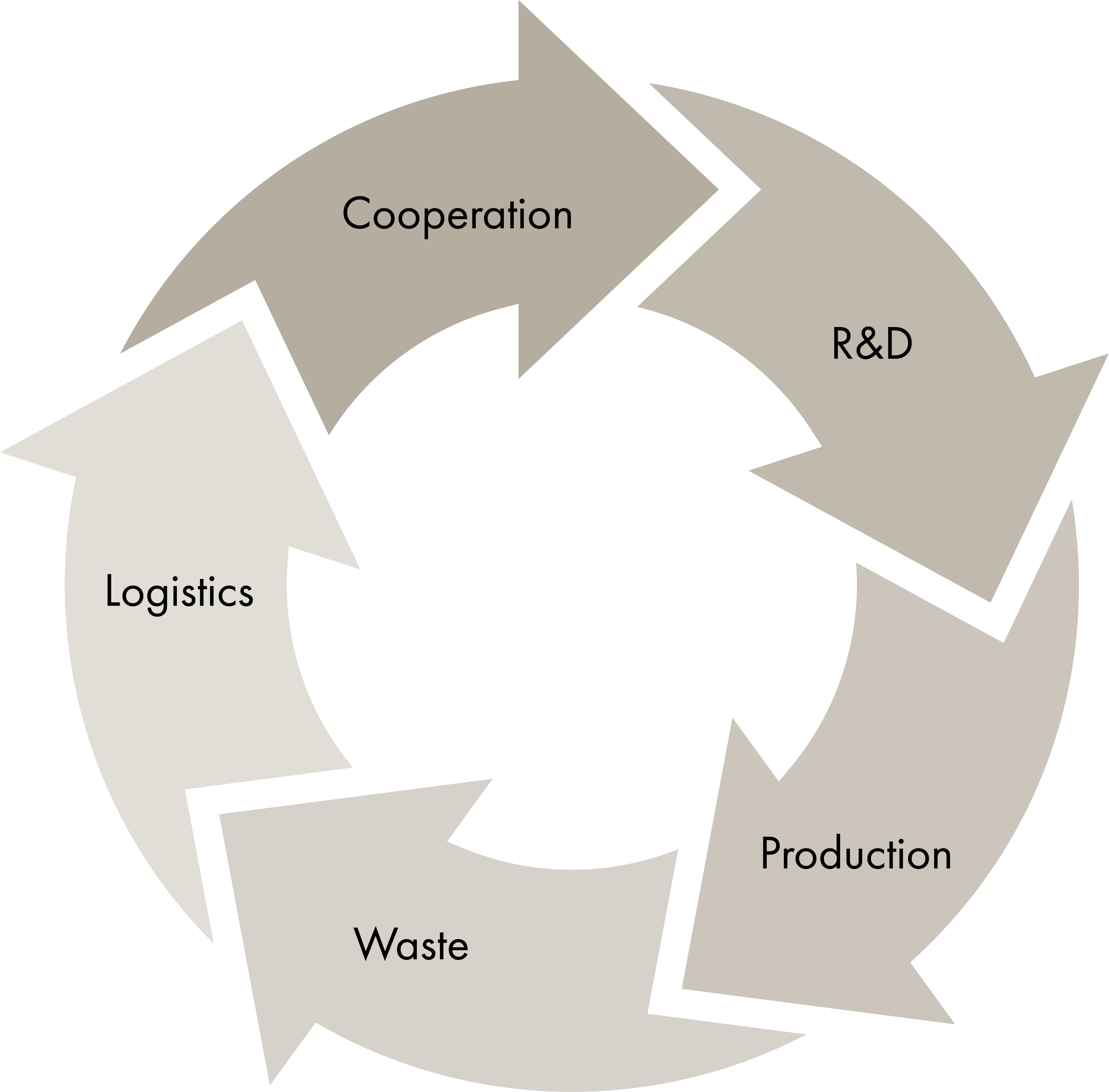

Sustainability is at the core of everything we do – from innovative product development and resource-efficient production to efforts to increase recycling and reduce carbon emissions.

We hold ourselves and our suppliers to high standards, requiring them to comply to our Supplier Code of Conduct.

We aim to increase the use of recycled materials, particularly recycled plastic – but we cannot achieve this alone. The choices and priorities of our customers play a crucial role in our joint effort to create a more circular future

Make a Difference with Us! Want to learn more about the sustainable plastics we use in our packaging? Click here.

Here, you can explore some of our collaborations and initiatives for a more sustainable future.

Small Insects, Big Impact

About one-third of the food we eat is pollinated by bumblebees and honeybees. However, biodiversity has declined drastically in recent decades. Insects play a crucial role in the ecosystem, including pollination. We are proud to support biodiversity and have placed a beehive with 30,000 bees at our Western factory site.

ISCC+, Responsible Plastic

Modulpac are certified according to the ISCC+ standard.

ISCC+ (International Sustainability & Carbon Certification) is a globally recognized standard that ensures traceability throughout the value chain – from raw material to finished product.

By using certified bio-circular materials through mass balance approach, we can reduce reliance on fossil resources, lower carbon emissions, and support the transition to a circular economy.

Avery

A well-functioning circular economy requires efficient waste management and cooperation. We work with Avery Dennison to recycle the glassine liners, which was previously incinerated. Through this initiative, we ensure that even more materials get a second life.

Read more: Helping Modulpac recycle and reduce waste with AD Circular – Avery Dennison

Workplace safety – A Safe and Secure Workplace

We actively work to prevent workplace accidents through systematic work environment management and continuous improvements in occupational safety.

Our employees share the responsibility of following safety procedures, reporting risks, and contributing to a safe work environment. To further strengthen this, we have a safety committee that regularly evaluates and implements measures to minimize risks and enhance engagement and cooperation for our workplace safety.

Our goal: Zero workplace accidents resulting in sick leave.

Reduced CO₂ emissions – Energy Transition for Greener Production

A successful climate strategy requires a shift toward sustainable energy.

At our Western factory, we have installed a 7,000 m² solar panel system, which was completed in 2024. This investment allows us to reduce approximately 8% of the electricity from the grid.

Closure2Closure – A Circular Solution for Closures

With our Closure2Closure project, we take a step closer to a circular plastics industry. By using 100% recycled material in the production of closures, we reduce dependence on fossil plastics and promote sustainable resource use.

The plastic comes from collected and recycled materials, contributing to lower carbon emissions and the reduction of plastic waste. Closure2Closure is part of our commitment to creating packaging solutions where materials can be recycled and reused more than one time– just as a circular economy should function.

Together with our customers and partners, we drive the development toward a more sustainable future!